Sealed Coaxial Needle-KIT

Sealed Coaxial Needle-KIT

Our Sealed Coaxial Needle-KIT is the ideal solution for Core-Shell electrospinning for any type of polymer, even in the most corrosive solvents.

SUITABLE FOR CORE-SHELL ELECTROSPINNING

All our needles are manufactured in AISI 316 stainless steel and are assembled entirely by a laser welding process. Thanks to the manufacturing material, it is possible to spin any type of polymer, at a temperature up to 120°C in standard configuration.

WHAT ADVANTAGES DO YOU GET FROM USING THIS KIT?

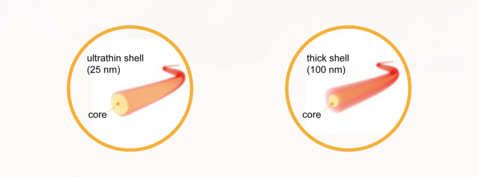

With coaxial needles, you gain the ability to spin two or more polymers simultaneously within the same fiber. This can allow for the production of fiber with an inner core and outer shell.

This may be useful for cases where the use of only one material may result in having to compromise between two material properties- for example, the mechanical strength of one material is desirable, but a different material shows a better degradation rate.

Two standard versions are available with two or three concentric layers, which can be customized upon request.

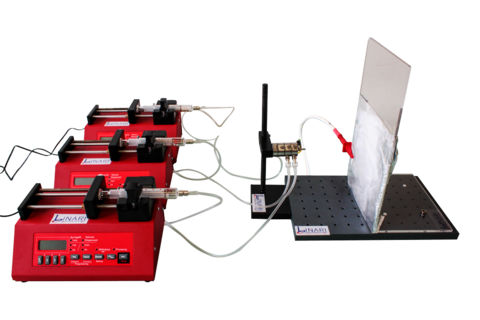

These needles are very compact and make it possible to create high productivity configurations since they can be assembled in parallel up to tens of units thanks to a simple, solid mechanical structure and the distribution of the solutions through Luer-UNF connections.

The rear threaded hole permits both the fastening to the support structure and the stable connection of the high voltage.

LOOKING FOR A VERSATILE SOLUTION?

In our Coaxial Needle Kit, every concentric needle is independent so that it can be equipped with a different diameter and be supplied with solutions of different materials through standard Luer Lock connections.

PRODUCTS INCLUDED

- Sealed Coaxial Needles.

- Dielectric Support.

- Coaxial Needles Fittings: 2pcs (2layers( / 3 pcs (3layers).

STANDARD DIMENSIONS

Outer needle: G11

- od: 3.05 mm.

- id: 2.39 mm

Middle needle: G15

- od: 1.83 mm.

- id: 1.37 mm.

Inner needle: G21

- od: 0.83 mm.

- id: 0.51 mm.

COMPATIBILITIES

It can be integrated on machines that have a number of pumps per syringe equal to the number of layers used.

Share