RT Advanced

RT Advanced

The most technologically advanced electrospinning machine for industrial production and advanced research.

RT Advanced is for research centers, universities, technological companies that need to produce high quality, reproducible nanomaterials, for both experimental and commercial purposes.

RT ADVANCED: THE MOST POPULAR ELECTROSPINNING SYSTEM TO WORK FULLY UNMANNED

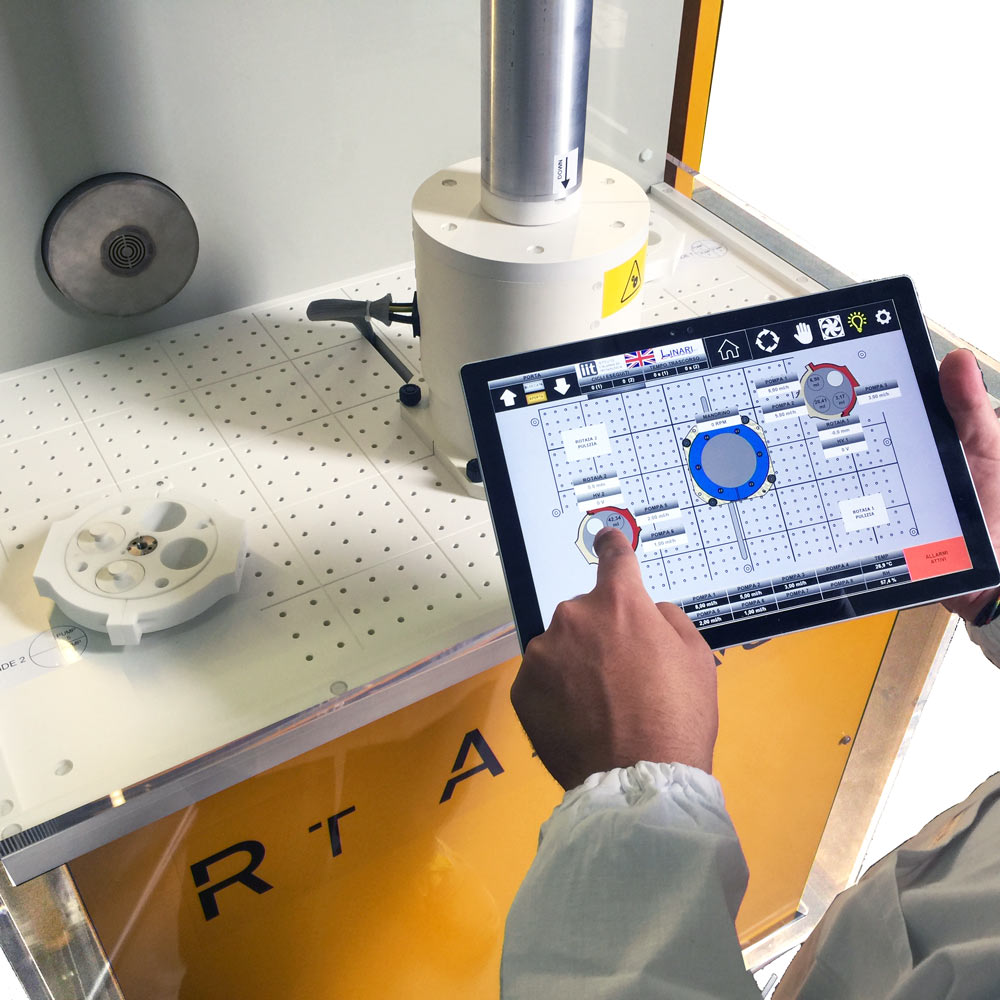

If you are looking for a full optional machine with high productivity, RT Advanced certainly is the right system for you. With this machine, you'll be able to work with up to 8 different materials at the same time.

See the machine in action

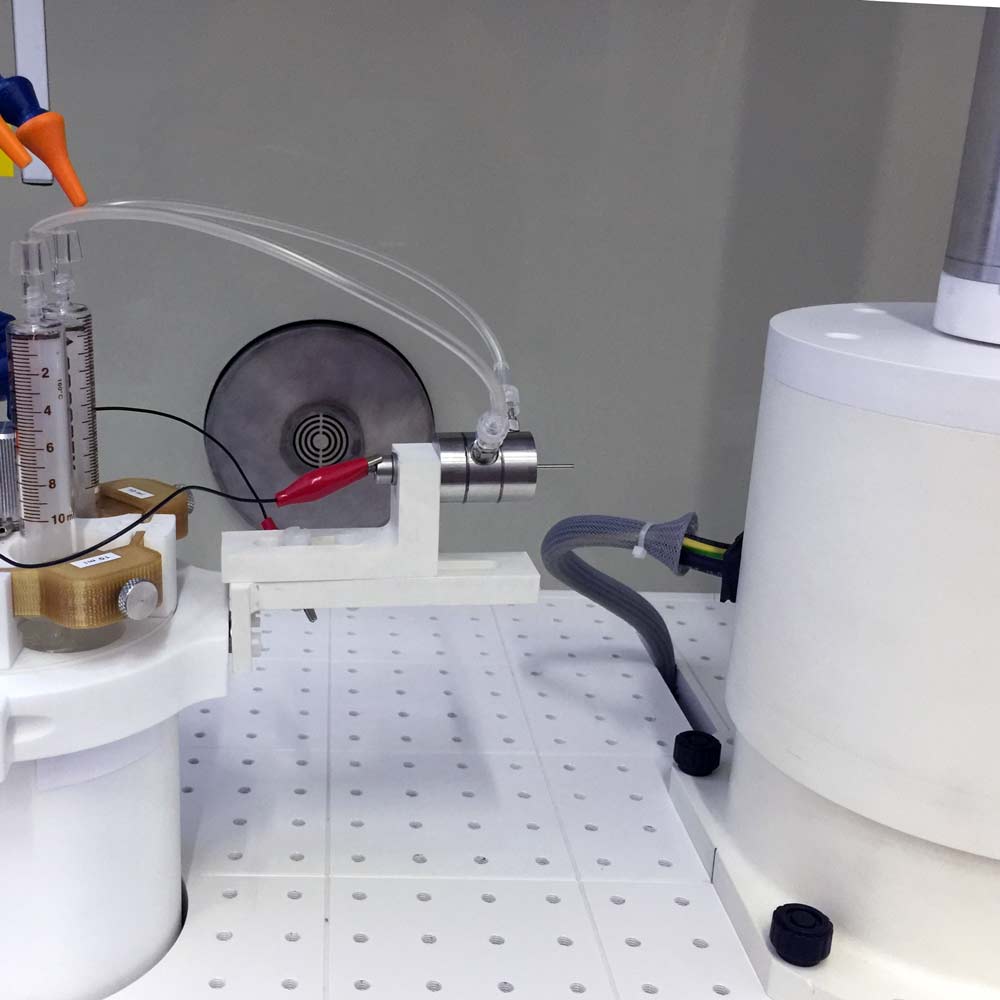

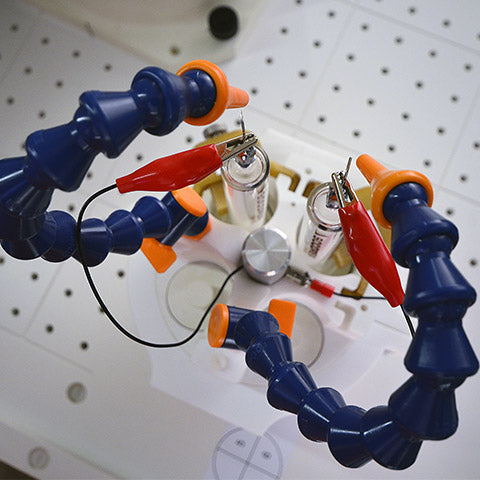

The peculiarity of this system is that the collector stays fixed, while the syringes move on the vertical axis. This technology, combined with the vertical collector and the machine weight of 300kg, allows reaching a speed up to 5000 rpm without causing oscillation and remaining a quiet device.

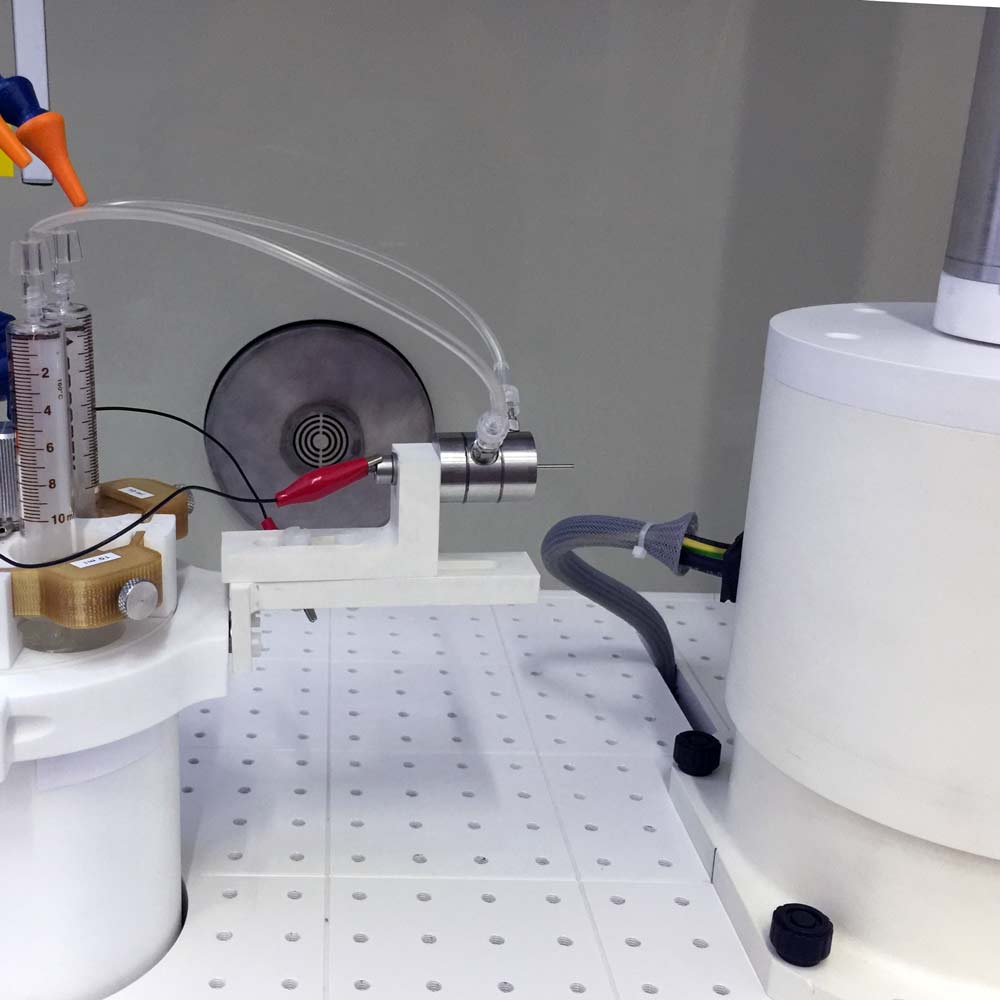

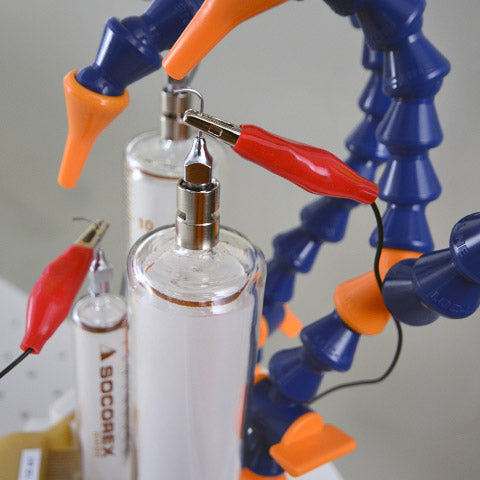

Compared to other systems, RT Advance is the only system able to move the syringes without using tubes. By working with tubes, a huge quantity of material remains inside them. That causes a waste of the material and a need to regularly replace tubes. With this advanced machine instead, this won't be a problem.

The knowledge of our engineers, together with an analysis of our customer's requests, lead us to work with fully programmable pumps, completely independent.

Using the Omron Electronics Industrial components, the electronic control has maximum reliability, under heavy working conditions too.

In case of blackout or malfunction, the system will be automatically interrupted.

Option: Laser Measuring System

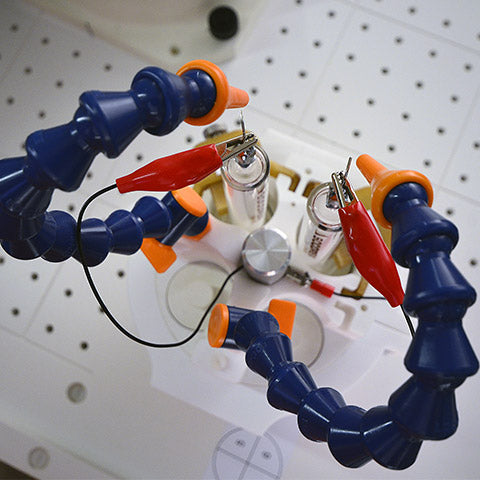

Real Time quality control: Being the fibers extremely soft and thin, calipers or micrometersare not suitable to measure the number of nanomaterials produced. Through the optical system of Omron technology, we can now monitor in real-time the thickness of the fibers, to an accuracy of 10 nanometers.

What materials can you electrospin?

With the RT Advanced it is possible to electrospin any type of synthetic, organic polymer or ceramic material, starting from solutions at room temperature.

What quality and quantity of nanofibers do you get?

You can create deposits of nanofibers with chaotic or perfectly oriented structure by simply changing the operative settings. The nanofibers are characterized by high reproducibility over time, with the possibility of depositing up to four different materials at the same time.

Technical features of the device:

- WiFi controller with a 12.3" Microsoft Surface Pro 4 Tablet-PC.

- Access and visibility on three sides of the electrospinning chamber.

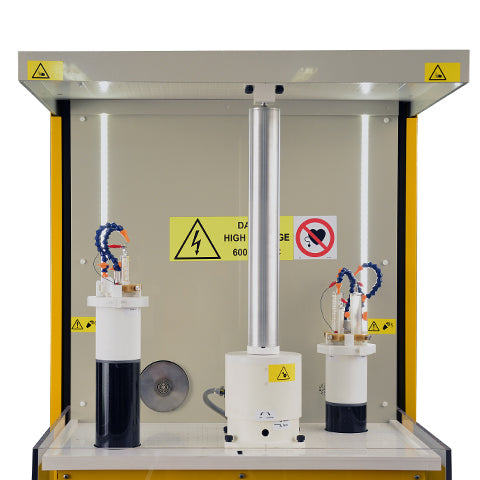

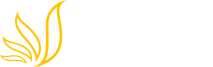

- Built-in high voltage 60 kV generator.

- Up to 8 pumps for independent syringes.

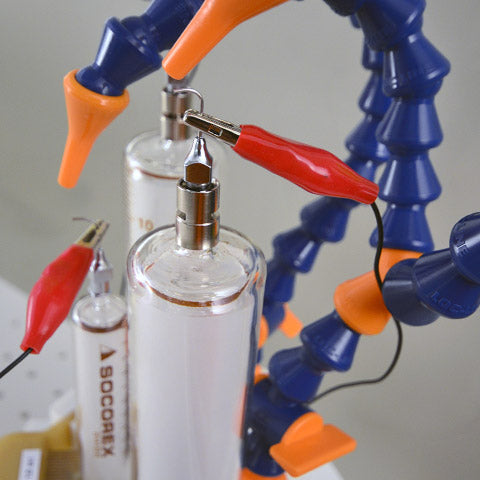

- Multi-needle or coaxial needle system.

- Easy to replace flat or drum collectors, between 1 to 250 mm in diameter, maximum length 500 mm.

- The collector can rotate both clockwise or anticlockwise.

- Vertical axis of rotation of the collectors up to 5000 rpm for the creation of tubular structures with aligned fibers.

- Vertical axis of a continuous belt for the creation of flat substrates with length up to dozens of meters.

- Automatic cleaning of the needles with timed jets of compressed gas.

- Control of internal temperature and humidity, flushing with inert gases- RT - 50 °C, 20% - 70% RH.

- Built-in suction system.

The collector is insulated from the ground so that it can be connected to a second high voltage generator up to a potential of +/- 60kV.

General Information

| GENERAL |

UNIT | VALUE | NOTE |

| Depth dimension |

mm | 1035 | |

| Height dimension | mm | 2200 | |

| Width dimension | mm | 1050 | |

| Total weight | kg | 400 | about |

| Max electrical power consumption | kW | 1,5 - 4 | following optional installed |

| Supply voltage | V AC | 230 | single phase 50-60 Hz |

| Ventilation system | Yes |

| Temperature control system | Optonal: heating only, heating/cooling, drying |

| Warranty | 1 Year |

Technical advantages of the device

- Unique: what makes the RT Advanced unique is its original structure composed of one or more vertical axis rotating chucks along which the syringes and their needles move.

- Replacement of the collectors: simple and fast replacement of the collectors, even if they are large, thanks to the single lower self-centering chuck.

- No waste: the loading of the syringes is done without wasting solution due to the absence of flexible tubes which connect them to the needles.

- Silence: the vertical movement of the needles along the collector reduces the size of the machine and eliminates vibrations during operation, even at high speed.

- Second high voltage generator: the collector is insulated from the ground so that it can be connected to a second high voltage generator up to a potential of +/- 60 kV.

- High quality components: all the materials used have been carefully selected to avoid interference on the electric field between collector and needles for maximum control of the nanofiber deposition, avoiding waste and improving the morphology of the substrate.

- Reliability: the use of Omron Electronics industrial components for the control electronics guarantees the maximum reliability of the system also under heavy use conditions.

Safety

- Opening of the spinning chamber is blocked when high voltage is present.

- Control system for the automatic interruption of production in case of blackout or malfunction.

- System of active control to eliminate sparks and high voltage discharges.

Share