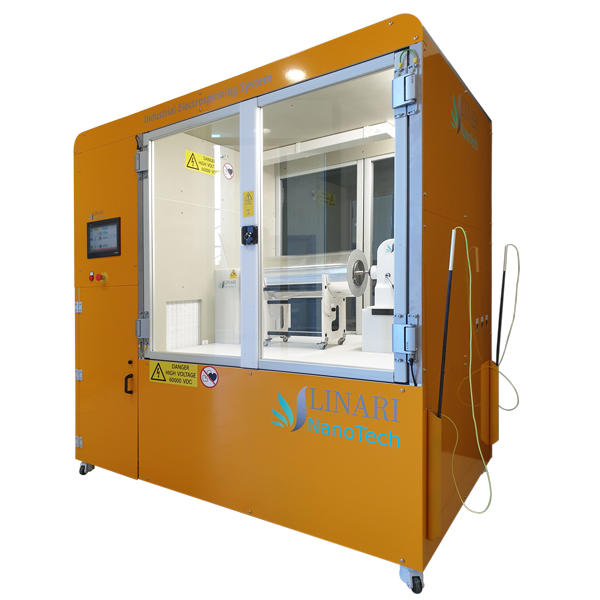

Pilot Spinner

Pilot Spinner

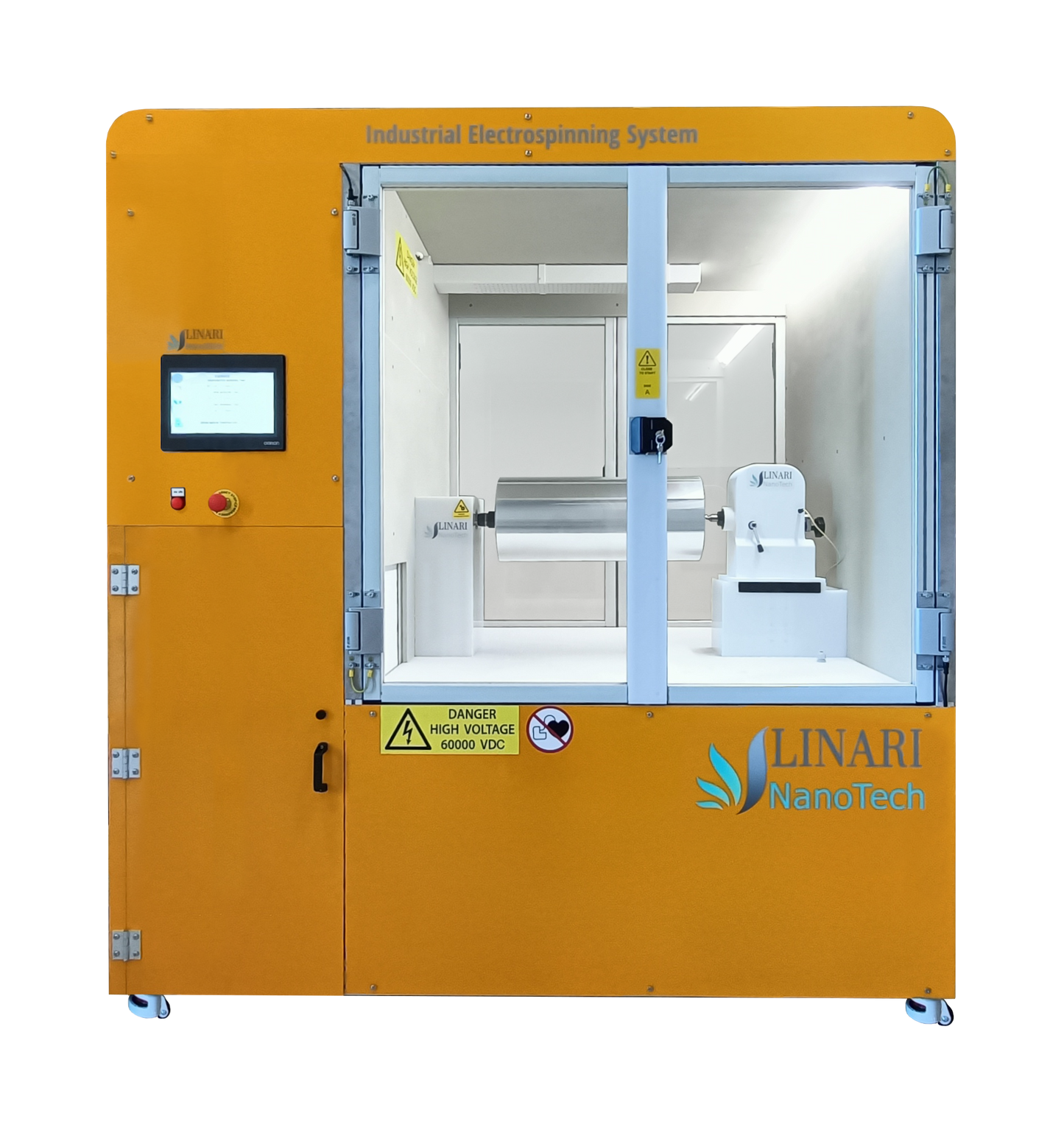

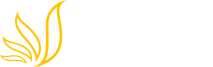

The highest productivity electrospinning machine for industrial production and advanced research.

Pilot Spinner is for research centers, universities, technological companies that need to produce high quality, reproducible nanomaterials, for both experimental and commercial purposes.

The perfect machine for your pilot industrial production

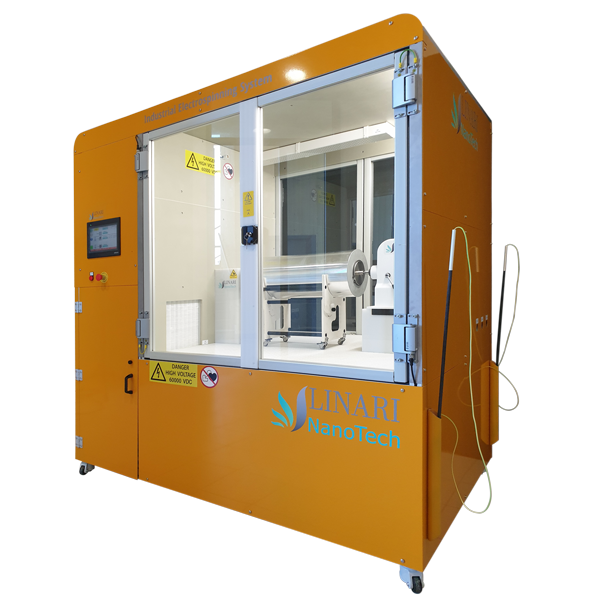

If you are looking for a machine with high productivity and great freedom to operate, Pilot Spinner certainly is the right system for you. With this machine, you'll be able to work with large collectors and install optionals to scale up.

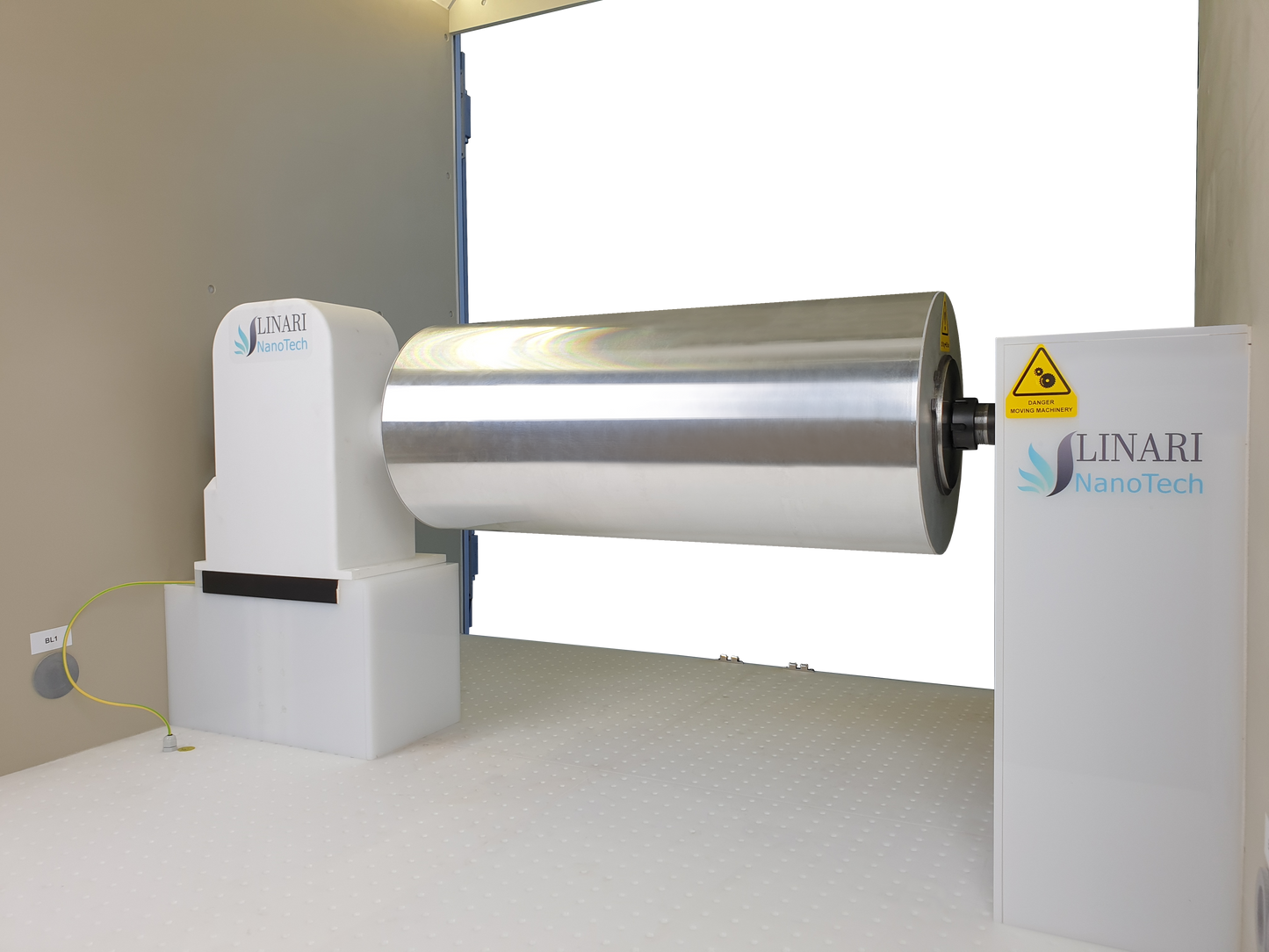

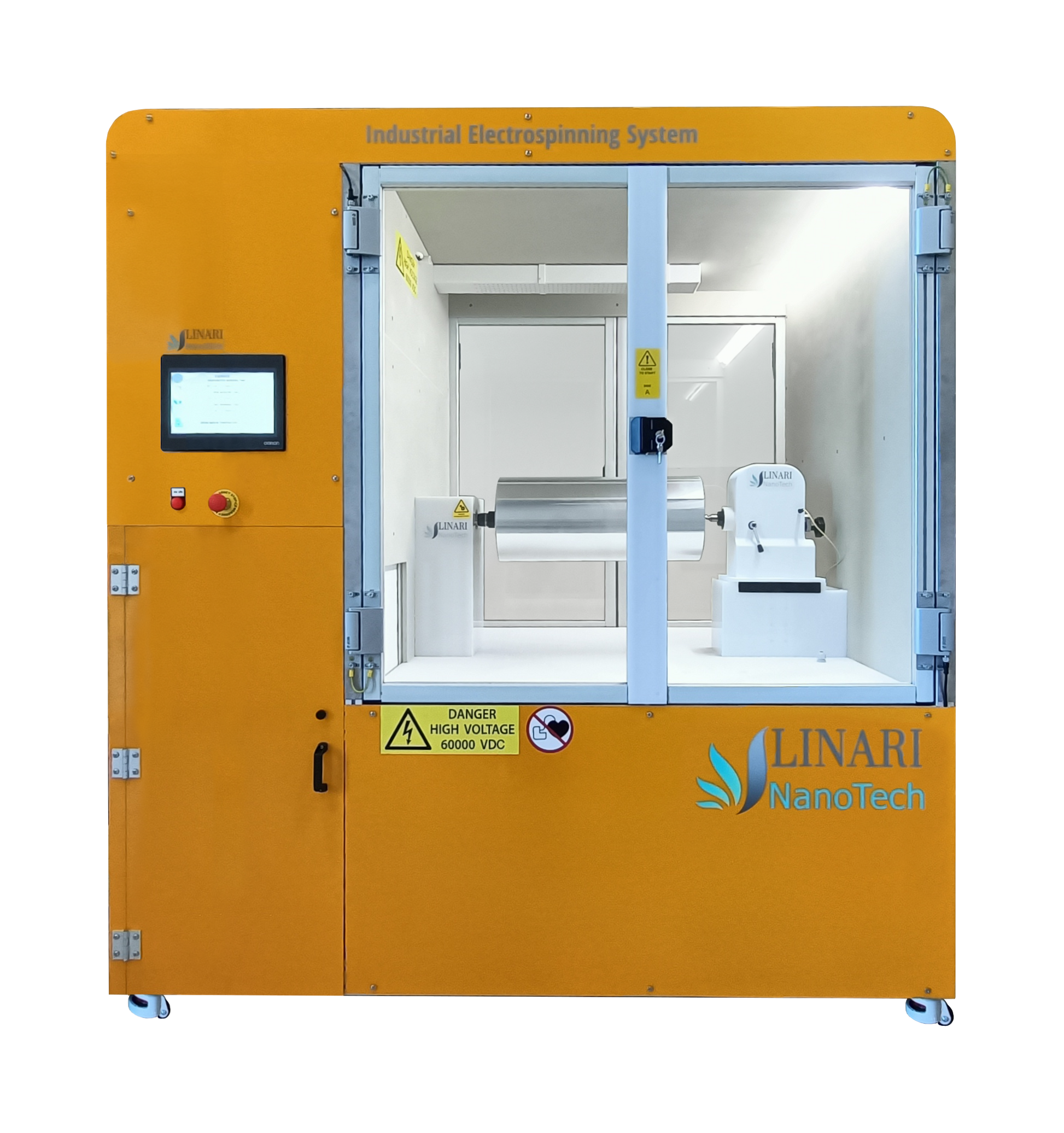

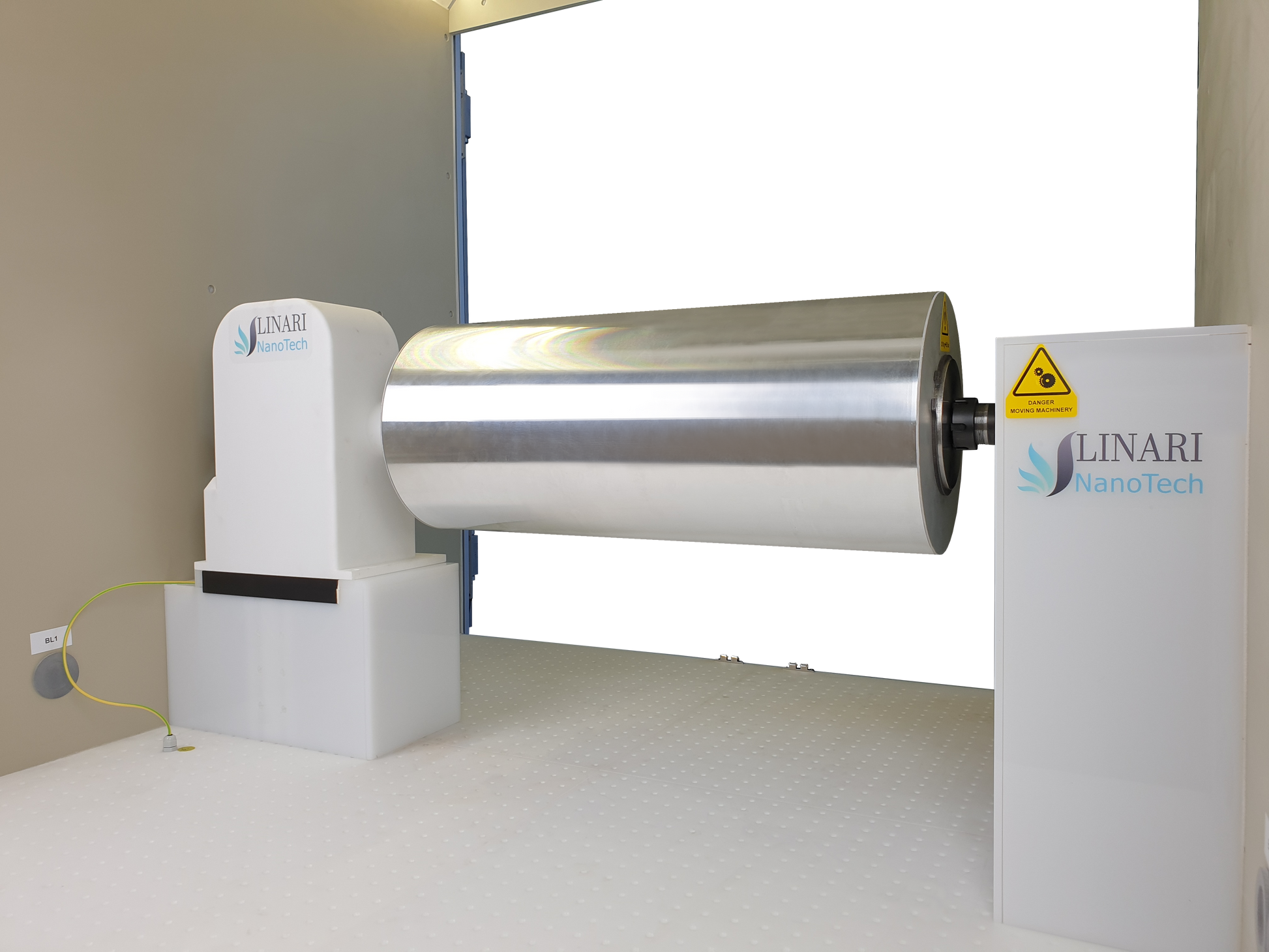

The peculiarity of this system is that the drum collector can be up to 600 mm lenght and 250 mm diameter. This technology, combined with a large electrospinning chamber and the double door with double HMI display on front and rear side, let you work with great freedom of customization of the electrospinning setup.

Using the Omron Electronics Industrial components, the electronic control has maximum reliability, under heavy conditions too.

In case of blackout or malfunction, the system will be automatically interrupted.

What quality and quantity of nanofibers do you get?

You can create deposits of nanofibers with chaotic or perfectly oriented structure by simply changing the operative settings. The nanofibers are characterized by high reproducibility over time.

Technical features of the device:

- Two 10.1" LCD color touch screens, one on each side of the machine to allow an easy high voltage and rotation unit management.

- Access and visibility on two opposite sides of the electrospinning chamber.

- Built-in high voltage 60 kV generator.

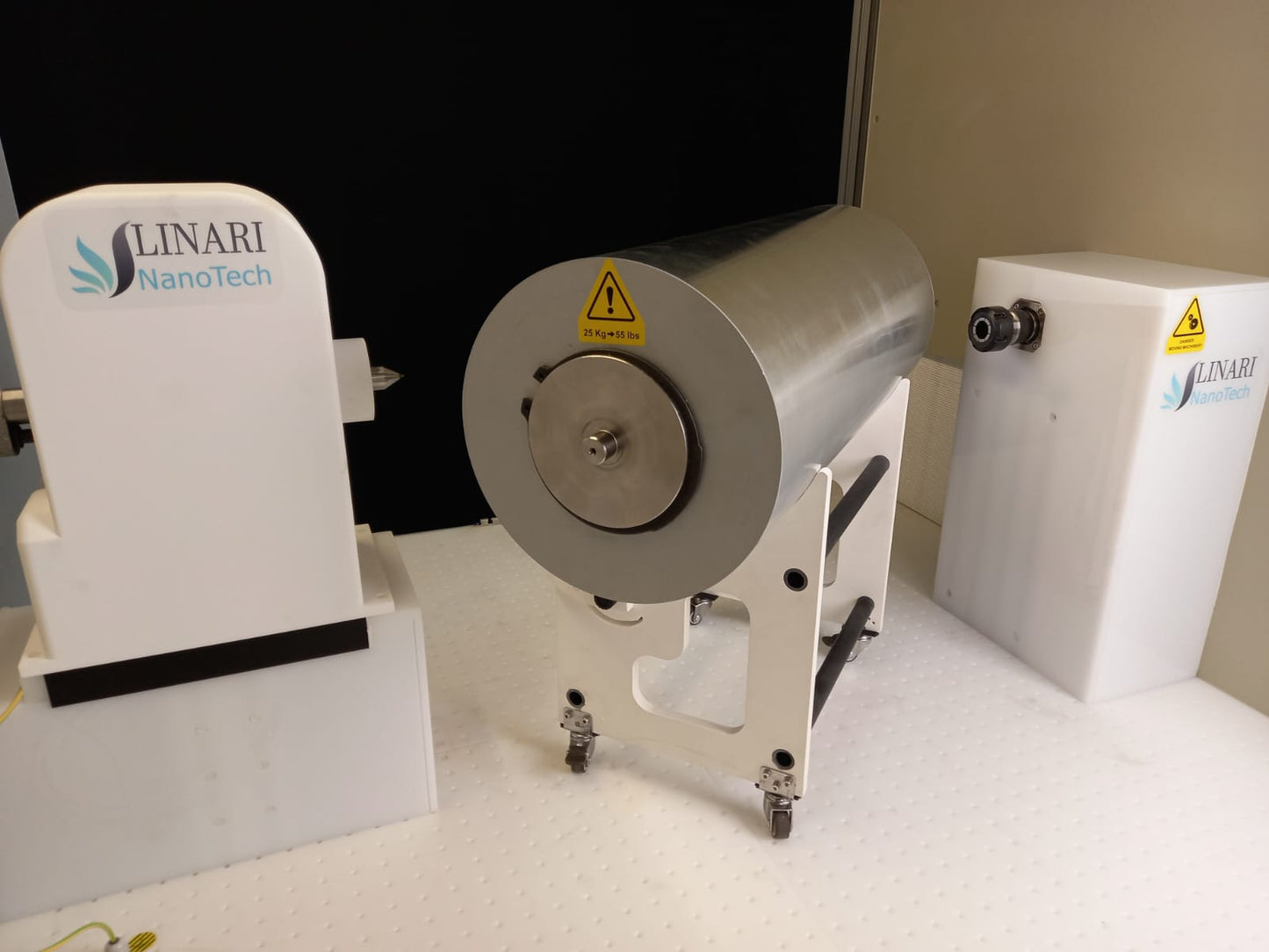

- Easy to replace flat or drum collectors, between 1 to 250 mm in diameter, maximum length 600 mm.

- The collector can rotate both clockwise or anticlockwise.

- Ventilation: 0,18 kW.

- Internal illumination: led 3000 lumens.

The collector is insulated from the ground so that it can be connected to a second high voltage generator up to a potential of +/- 60kV.

General Information

| GENERAL |

UNIT | VALUE | NOTE |

| Depth dimension |

mm | 1295 | |

| Height dimension | mm | 2060 | |

| Width dimension | mm | 1880 | |

| Total weight | kg | 600 | about |

| Max electrical power consumption | kW | 2.7 |

depending on installed optionals |

| Supply voltage | V AC | 230 | single phase 50-60 Hz |

| Ventilation system | Yes |

| Temperature control system | Optonal: heating only, heating/cooling, drying |

| Warranty | 1 Year |

Technical advantages of the device

- Replacement of the collectors: simple and fast replacement of the collectors, even if they are large, thanks to the specific carrier.

- High quality components: all the materials used have been carefully selected to avoid interference on the electric field between collector and needles for maximum control of the nanofiber deposition, avoiding waste and improving the morphology of the substrate.

- Reliability: the use of Omron Electronics industrial components for the control electronics guarantees the maximum reliability of the system also under heavy use conditions.

Safety

- Opening of the spinning chamber is blocked when high voltage is present.

- Control system for the automatic interruption of production in case of blackout or malfunction.

- System of active control to eliminate sparks and high voltage discharges.

Share